keysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988glkeysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988glkeysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988glkeysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988glkeysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988glkeysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988glkeysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988glkeysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988glkeysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988glkeysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988glkeysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988glkeysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988glkeysight:dtx/solutions/facets/industry/semiconductor,keysight:dtx/solutions/facets/workflow-stage/manufacturing,segmentation:business-unit/EISG,segmentation:campaign/IC_Semi_Mfg,segmentation:product-category/IC_Semi_Mfg/InCircuit_Test_Systems,keysight:product-lines/80,segmentation:funnel/tofu,keysight:dtx/solutions/facets/development-area/power,keysight:dtx/solutions/facets/design-and-test-product/board-test,keysight:dtx/solutions/facets/industry/automotive,keysight:dtx/solutions/facets/industry/wireline-communications,segmentation:product-category/IC_Semi_Mfg,keysight:models/e9/e9988gl

How to Test Passive Components without Access Points

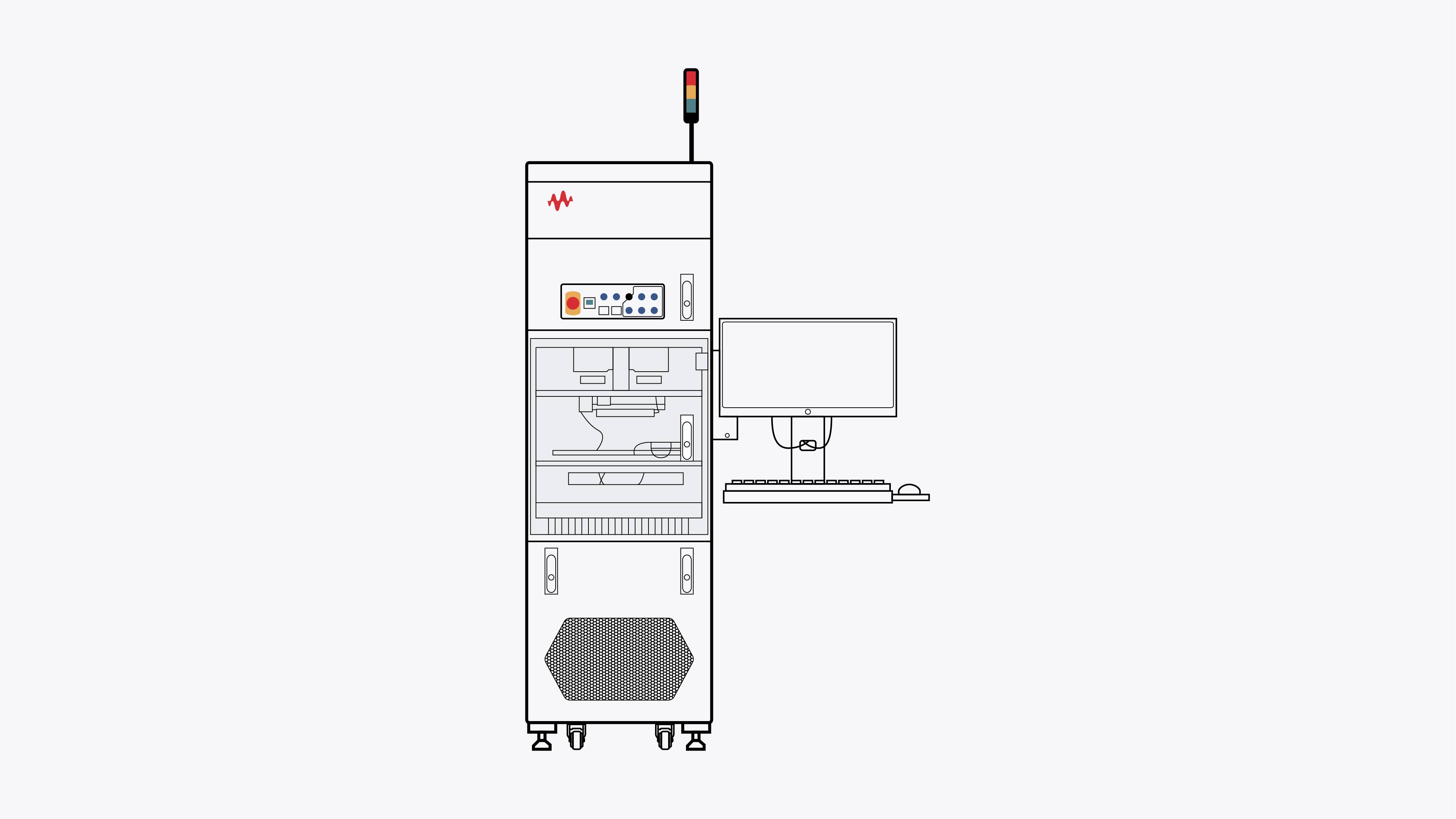

Testing passive components on high-density PCBAs without test points necessitates grouping components into clusters and calculating impedance for precise testing. Learn how the enhanced cluster test solution automates the cluster generation process, ensuring efficient and accurate testing.

Learn more