What are you looking for?

In-Circuit Test Systems

Keysight In-Circuit Test (ICT) system brings you technology for tomorrow's board test challenges.

Driving Confidence In

Automotive Electronic Testing

In today's automotive industry, ensuring the reliability of electronic components is mission-critical. From complex ECUs to simple wiper sensor boards and anti-collision sensors, these electronics are the lifeblood of modern vehicles, impacting safety, efficiency, and overall functionality.

Our in-circuit test product portfolio includes a wide range of board test solutions designed to meet the diverse needs of the automotive electronics testing landscape. Take our latest i3070 Series 7i, for example. This industry-leading system now includes specialized features explicitly tailored for automotive testing. These features encompass supercapacitor testing, faster shorts testing, LED diagnostics, and low-current measurements – all crucial tests required to test automotive electronics such as engines, transmission or safety electronics, and entertainment systems. With the i3070 Series 7i, you can enjoy peace of mind knowing that your automotive electronics will undergo comprehensive and reliable testing.

For those handling high-volume, low-complexity boards like anti-collision sensors and wiper boards, our award-winning i7090 offers a breakthrough solution. With the ability to simultaneously perform massively parallel board tests on up to 20 boards efficiently and accurately, testing these small electronic boards is now more cost-effective to enable better test coverage and reliability.

But we don't stop there. To further enhance your testing capabilities, we introduce the x1149 2.0. This state-of-the-art system, compliant with the latest IEEE standards, can be integrated with the i3070 or used as a standalone solution. Ensure confidence in the quality of your shipped automotive electronics by recovering test coverage of mission-critical ICs lost due to the limited access to electronic nodes.

Ready to explore our solutions? Find the board test solution that's right for you below, or talk to our specialists today for a tailored solution to your automotive electronic testing needs.

Find The Board Test Solution That's Right For You

Award-Winning Board Test Solutions

Discover the awards and recognitions our board test solutions have earned for innovation and superior performance. See why industry experts and customers trust our cutting-edge technology and unmatched quality.

Industry Insights and Networking

Each year, Keysight hosts a user group meeting (UGM) tailored for professionals in the manufacturing test industry. This event offers a unique opportunity for our customers to gain insights from industry experts on the latest challenges and solutions in manufacturing testing.

Join us at an event near you to expand your knowledge, enhance your expertise, and connect with top professionals in the field.

Related Use Cases

Extend Your Capabilities With The Right Tools

The Keysight Board test system software is feature-rich and explicitly designed for PCBA Manufacturing Test. These tools ensure the success of Boundary Scan testing at all stages of the product life cycle, from design to prototyping, NPI, and high volume production runs.

DFT Analysis Tool

DFT analysis tool is available as part of the x1149 SW. This tool provides insights into how well the DFT on the PCBA is performing in terms of ensuring high test coverage. Below is the link to the software application.

ICT Software

ICT is the most commonly used board manufacturing test in the manufacturing production line. To see what kind of test coverage you can get, click on the link below to download the i3070 ICT Software.

In-Circuit Test Systems Featured Resources

Frequently Asked Questions About In-Circuit Test (ICT)

In-circuit testing (ICT) is a critical performance and quality assessment method for printed circuit boards (PCBs). ICT is instrumental in detecting manufacturing faults such as short circuits, open circuits, irregular resistance, unexpected capacitance, and other discrepancies that could potentially hinder the optimal functioning of the final electronic product. Among the various PCB testing methods, ICT provides crucial testing capabilities that help manufacturers verify the functionality of their components and units, ensuring alignment with product specifications and capabilities.

Boundary scan testing, or Joint Test Action Group (JTAG) testing, is critical in electronic design and manufacturing. Boundary scans enable the functional examination of digital components, including integrated circuits (ICs), FPGAs (field-programmable gate arrays), and PCBs. The boundary scan process applies test patterns and observes corresponding responses, effectively pinpointing faults, short circuits, open circuits, and other potential defects.

ICT coverage represents the percentage of components and circuitry that an in-circuit test system can effectively test on a PCB. Higher coverage ensures a more comprehensive evaluation of the board's integrity and functionality.

The advantages of in-circuit testing include pinpointing faults at the component level, conducting simultaneous testing across multiple points, and swiftly and accurately evaluating intricate PCBs.

In-circuit testing in electronic manufacturing aims to detect defects or faults in individual electronic components or circuits during the production process.

In-circuit testing distinguishes itself from functional testing by concentrating on verifying the integrity and connectivity of individual components and circuits. In contrast, functional testing evaluates the overall performance of the electronic device.

In-circuit testing in electronic manufacturing aims to detect defects or faults in individual electronic components or circuits during the production process. In-circuit testing can identify defects such as incorrect component values verification, soldering defects, open circuits, short circuits, incorrect component placement, polarity issues, incorrect orientation, missing components, component misalignment, defective components, and faulty connections.

The main advantages of using in-circuit testing in quality control include early detection of defects, high test coverage, fast testing speeds, and the ability to perform tests on complex electronic assemblies.

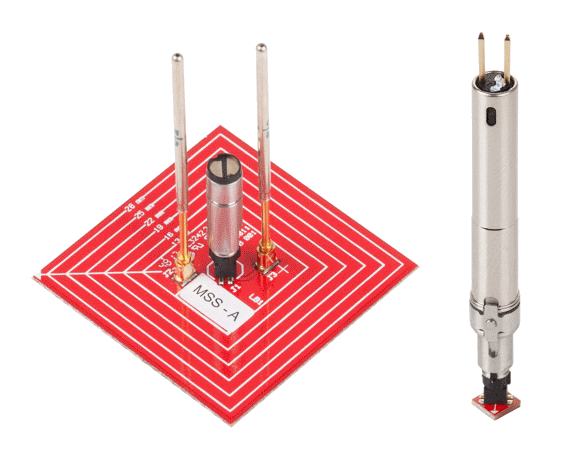

In-circuit testing on PCBs is typically performed using specialized test fixtures or bed-of-nails testers to make electrical connections with specific points on the board, after which test signals and measurements can be applied.

In-circuit testing contributes to overall production efficiency by enabling rapid fault detection, reducing rework and scrap, and ensuring the reliability and quality of electronic products.

In-circuit testing can be adapted for different types of electronic components by using specialized test probes, fixtures, and test algorithms tailored to the specific characteristics of each component.

Want help or have questions?